Manufacturer and supplier of ASME SA 789 UNS S32205 coiled Tubing, custom wall thickness in Inches/ mm

Duplex 2205 Tube is stainless steel tube. It belongs to a family of stainless steels called as the duplex steels. There are different groups of this material. The pipes of this family could be formed either by cold drawing of by hot rolling and welding. The Alloy 2205 Seamless Tube is cold drawn and it has less absolute roughness. The seamless ones are less strong than the Duplex SS 2205 Welded Tubing but are highly precise in dimension. The precision in dimension is useful in highly sensitive applications which require precision in measurements and calculations. The specialty of Duplex 2205 Seamless Tube is that it contains a dual nature. It is neither ferritic nor austenitic but contains the best of both parts. The Duplex 2205 Tube is a super duplex grade tube and it contains ferritic and austenitic steel phases in its structure. Therefore the strength and the corrosion resistance properties are improved. The Duplex 2205 Seamless Tube could be used in applications like the marine and underwater application which are exposed to chloride ion rich environments.

The ASTM A790 Duplex 2205 Welded Tube is stronger and also possesses the same corrosion resistance properties. It has less absolute roughness but has more strength than the seamless pipes. The 2205 Duplex Tube applications require different shapes, sizes and pressure classes of the pipes. The SA 789 Alloy 2205 4 inch Tube is used in medium range fluid transfers. There are other sizes that range from ½” up to 42” and more. Depending on the application requirements, the pipes are sometimes custom made. These are used in petrochemical, chemical, food processing, pulp and paper, oil and gas and organic acid production industries as well. The Duplex SS 2205 Schedule 40 Tube can withstand high pressure and is used in condensers and heat exchangers.

Liaocheng Sihe SS Material Co., Ltd. are duplex stainless steel tube suppliers. It is being manufactured by superior quality raw material with the guidance of highly qualified quality team. It is available in various sizes, grades and specifications.

Duplex 2205 tubes is the most widely used duplex stainless steel grade. It is nitrogen enhanced duplex stainless steel that is evolved to conflict common corrosion problems experienced with the stainless steels 300 series.

2205 duplex stainless steel tubes is two-phase, ferritic, austenitic 22% chromium, 3% molybdenum and 5 – 6% nickel alloyed stainless steel.

duplex steel tube is characterized by high yield strength, double that of the austenitic stainless steel standard grades. It also exhibits good fatigue strength, as well as outstanding resistance to stress corrosion cracking, pitting, crevice, erosion, and general corrosion in severe environments.

duplex steel tubes exhibits superior corrosion resistant properties to Stainless Steel 316 and 316L in most environments. It contentof chromium, nitrogen and molybdenum and also provide high pitting and crevice corrosion resistance, even in oxidizing and acidic solutions

duplex stainless steel tubing is resistant to chloride stress corrosion cracking and temperatures of up to 302°F. In caustic environments it provides for good performance due to the presence of ferrite.

duplex 2205 seamless tube has good oxidation resistance at high temperatures. It possesses good weldability and it should not be welded without filler metal as this may result in excessive ferrite. Its annealing temperature range is between 1868 – 2012°F.

The maximum hot forming temperature of duplex stainless steel heat exchanger tubes should be between the ranges of 2010 – 2100°F. It is somewhat more difficult to machine than austenitic stainless steels 300 series.

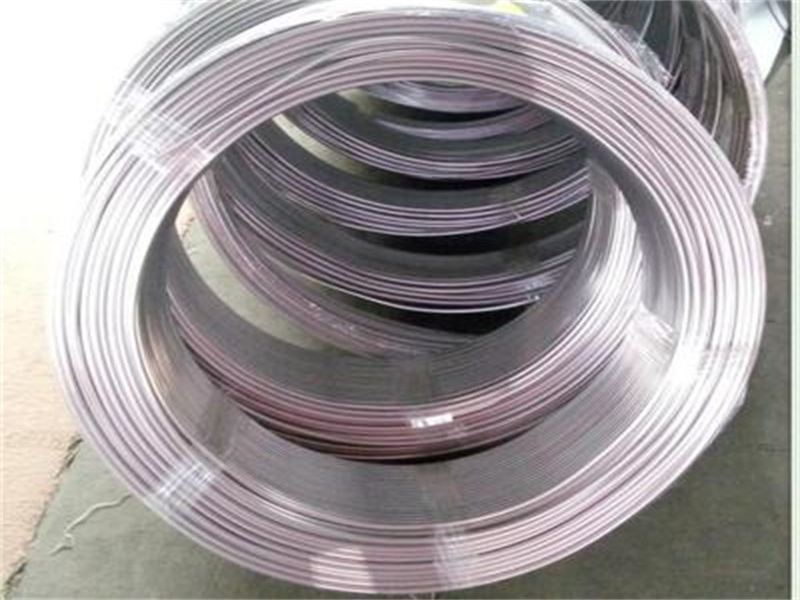

Duplex 2205 coiled Tubing photo

Exporter of Duplex 2205 heat exchanger tubes in China

| Spec Chart | ASTM A 790 ASME SA 790, ASME B36.10M, B36.19M |

| Size Range | 1/2 – 12 “NB IN |

| Pipe Sch. | SCH20, SCH30, SCH40, STD, SCH80 |

| Most popular types | Seamless / ERW / Welded / Fabricated |

| Forms Include | Round, Coiled, Hydraulic, Hollow |

| Pipe End Types | Bevel one end, Treaded Both Ends, Beveled One End, Bevel small end, Plain One End, Treaded One End, Bevel both ends, Plain Both Ends, Bevel large end, Beveled end |