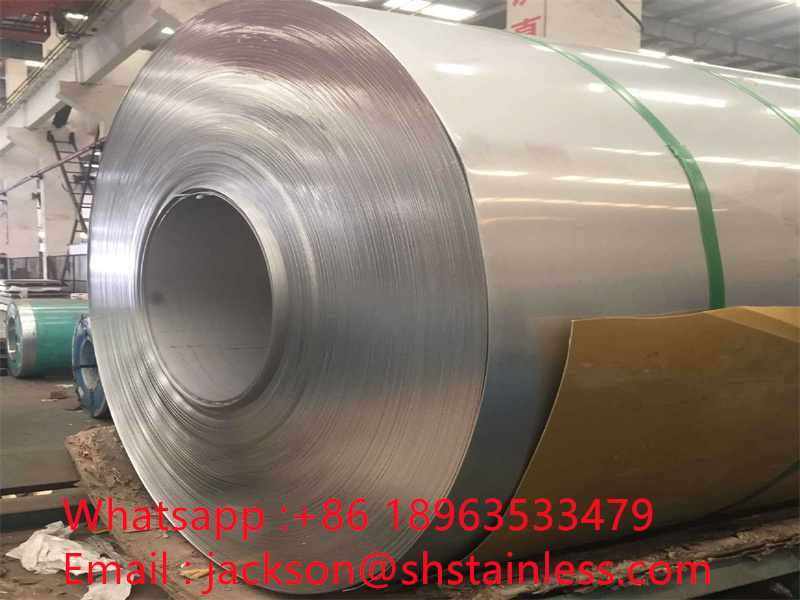

Cold rolled stainless steel coil Sheet 201 304 316L 430 1.0mm thick half hard stainless steel strip Coils Metal Plate Roll

PROFILE

201 stainless steel has a certain acid resistance, alkali resistance, high density, polishing no bubble, no pinhole and other characteristics, is the production of all kinds of watch case, watchband bottom cover quality materials. Mainly used for decorative pipe, industrial pipe, some shallow stretching products.

201 Stainless steel coil price is lower compared to other grades of stainless steels and all metallic products in general. There are different versions of the material with low carbon and high carbon content. The low carbon version, 201 coils are very good for welding applications as they have less carbide precipitation and less localized corrosion.

PRODUCT DESCRIPTION

| Product | 201 Stainless Steel Coil |

| Width | 10-2000mm or as customer’s requirements |

| Thickness | 0.1~16mm,or as customer’s requirements |

| Surface | N0.1, N0.4, 2D, 2B, HL, BA, 6K, 8K, Mirror,etc |

| Material | 201, 202 301, 302, 303, 303F, 303Cu, 304, 304L, 304H, 304F, 314 321, 316, 316L, 316Ti, 316F, 316LTi, 309S, 310, 310S, 904L 409, 410, 416, 420, 430, 430F, 431, 436, 439, 441 317, 317L, 347H, 329, 630, 631, 17-4PH 2205, 2507, 2304, HASTELLOYC-276, C-22, C-2000, MONEL400, 254SMO, 253MA, Inconel1600, Inconel1625, Incoloy800, Incoloy800H, Incoloy825, Incoloy800HT GH3030, GH3039, GH2747 |

| Standards | JIS, AISI, ASTM, GB, DIN, EN, etc |

| Certifications | ISO, SGS, BV |

| Packing | Industry standard packaging or according to client’s requirement |

| Delivery time | Within 3 days for our stock size,15-20days for our production |

201 EQUIVALENT GRADES

| STANDARD | UNS | JIS | WERKSTOFF NR. | AFNOR | BS | GOST | EN |

| SS 201 | S20100 | SUS 201 | 1.4372 | – | – | – | – |

201 PHYSICAL PROPERTIES

| Standard | Properties | Metric | Imperial |

| SS 201 | Density | 7.86 g/cm3 | 0.284 lb/in³ |

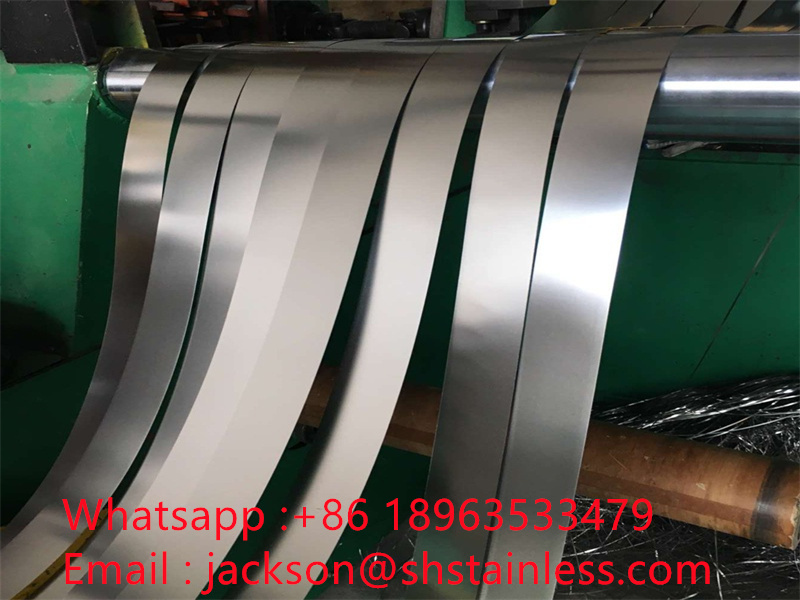

INVENTORY SIZE

| Stainless Steel Coil/Sheet/Plate Information | ||||||||||

| Technique | Surface Finish | Grade Series | Thickness(mm) | Width(mm) | Application | |||||

| Main Dimension | ||||||||||

| 20-850 | 1000 | 1219 | 1240 | 1250 | 1500 | |||||

| Hot Rolled | No.1 / 2E | 201/202/304 | 2.2-12.0 | √ | √ | √ | √ | √ | Petro-chemical industry,Tanks Construction material |

|

| Cold Rolled | 2B | 201/304 | 0.25-3.0 | √ | √ | √ | √ | √ | √ | |

| 410S/430 | 0.25-2.0 | √ | √ | √ | √ | |||||

| Hairline | 201/304 | 0.22-3.0 | √ | √ | √ | √ | √ | |||

| Mirror | ||||||||||

| SB | 410S/430 | 0.25-2.0 | √ | √ | √ | √ | √ | |||

| BA | 201/304 | 0.2–1.8 | √ | √ | √ | √ | ||||

| 410S/430 | 0.25-2.0 | √ | √ | √ | √ | |||||

| 2BA | √ | √ | √ | √ | ||||||

SURFACE FINISH

| Surface Finish | Definition | Application |

| 2B | Finished by heat treatment , picking or equipvalent cold rolling , followed by skin pass to obtain adequate luster surface. | With bright and smooth surface ,easy for further grinding to obtain brighter surface ,suitable for medical instruments ,milk containers ,tableware and so on. |

| BA | Bright heat treatment after cold rolling. | Structual members .etc.kitchen utensil ,cutlery ,eleltric applicances ,medical instruments ,building decorations ,etc. |

| NO.3/NO.4 | Polished with No.150-240 abrasives. | Milky food processing equipment , medicalinstruments ,building decorations. |

| HL | Finshed by polishing with abrasives of suitable grain size to obtain continuous streaks. | Building decorations ,such as elevators ,escalators ,door etc. |

| 6K/8K | A mirror-like reflective surface ,which is obtained by polishing with successively finer abrasives and buffing extensively with all gritlines are removed. | Buliding entrances,bulkding column casting ,elevator’s wall doors, counters,sculptur |

Write your message here and send it to us