ASTM A269 TP304/304L, 316/316L Stainless Steel Tubing Coil

Product Description

| 304/L (UNS S30400/UNS S30403) CHEMICAL COMPOSITION % (MAX .) | |||||||

|---|---|---|---|---|---|---|---|

| Cr Chromium |

Ni Nickel |

C Carbon |

Mo Molybdenum |

Mn Manganese |

Si Silicon |

Ph Phosphorus |

S Sulfur |

| 18.0-20.0 | 8.0-12.0 | 0.030 | 0.0 | 2.00 | 1.00 | 0.045 | 0.30 |

| 316/L (UNS S31600/UNS S31603) CHEMICAL COMPOSITION % (MAX .) | |||||||

| Cr Chromium |

Ni Nickel |

C Carbon |

Mo Molybdenum |

Mn Manganese |

Si Silicon |

Ph Phosphorus |

S Sulfur |

| 16.0-18.0 | 10.0-14.0 | 0.030 | 2.0-3.0 | 2.00 | 1.00 | 0.045 | 0.30* |

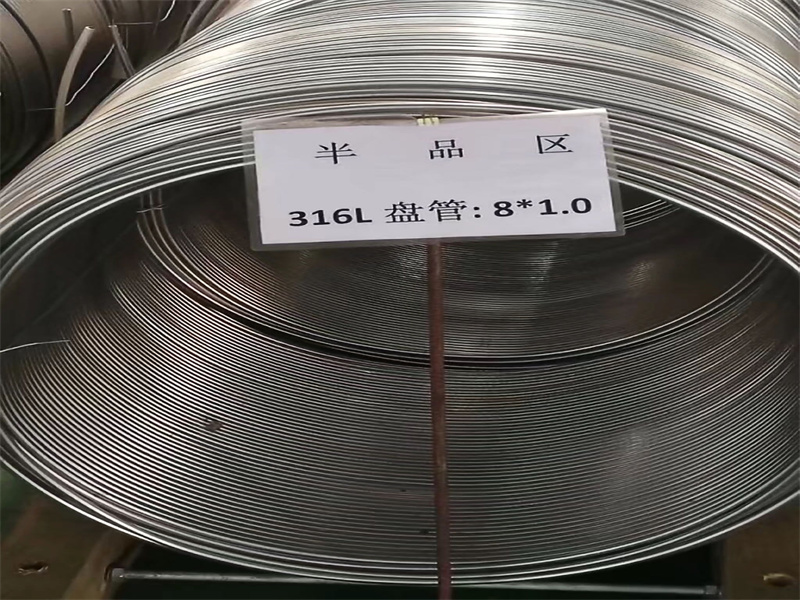

Quality Coil Tubing

We are a specialist for coil tubing, having the expertise and techniques to meet tubing bend service, all the tubing is conducted in 100% tested at the appropriate pressure, tubing inner and outer surface is clean and try for packing,

- Precision bending

- Smooth bends

- Surface roughness Ra < 0.5 μm

- Standard tolerance: ASTM A269, or D4/T4

After annealing, straighten stainless steel tubing is soft, tubing can be bent, formed, fabricated in various directions and angles, for heat exchanger system, typical tubing is U bend and coil tubing, also for food industry, they are food grade stainless steel.

Standard Stainless Steel Tubing Coil Dimensions

Stainless steel tube is designed in coiling form, general small diameter, maximum tube length can be 1000 meters, without any joint metal, there are a large range sizes of stainless steel tubing for coiling, standard outside diameter is given below, and wall thickness ranges from 0.0275 inch – 0.083 inch, maximum length reach to 1000 meters.

Bright Annealing Stainless Steel Tubing Coil

We offer welded and seamless tube in coiling shape, cold dawn should be carried out, if required, precise drawn process is available, to obtain smooth surface, tubes can be processed bright annealed finish.,

Advantages Of Coiled Tubing

Stainless steel tubing coil have excellent high temperature resistance and corrosion resistance, compared to cooper tube, stainless tube thickness can be reduced 30% – 60%, not too thin and too thick, it is not rust and sanitary, reducing maintenance time, saving cost, easy to install and change.